We build digital products to help businesses succeed!

Introduction

In the realm of AI manufacturing, a transformative wave is reshaping the industry. As we stand on the brink of a new era, predictive maintenance and process optimization AI are not just buzzwords but pivotal tools driving unprecedented efficiency and innovation. According to a Gartner report, by 2021, 20% of all manufacturers had already embraced AI-based automation for large-scale standardization. McKinsey furthers this narrative, stating that AI’s full potential in manufacturing is often hindered by data quality issues, yet overcoming these can unlock significant value.

These statistics not only validate the momentum of AI in manufacturing but also underscore the critical need for industries to adapt and evolve. As we delve into the world of AI in manufacturing, we uncover how it not only streamlines operations but also fosters an environment ripe for breakthroughs, setting the stage for a future where machines not only do but also think and learn. This blog will explore the transformative impact of AI on the manufacturing industry, backed by industry examples that highlight the tangible benefits of this technological evolution.

How Can AI Help Manufacturing? 10 Real World Examples

The integration of AI in manufacturing is revolutionizing the industry, offering solutions that enhance efficiency and foster innovation. By harnessing the capabilities of AI manufacturing, predictive maintenance, and process optimization AI, companies are setting new standards for innovation and sustainability in the industry. As AI manufacturing companies continue to evolve, the use of AI production systems and AI manufacturing robots will become increasingly prevalent. Let’s have a look at ten real-world examples illustrating the same:

- Predictive Maintenance with AI:

AI’s predictive capabilities are a game-changer for maintenance strategies. By analyzing vast amounts of data from machine sensors, AI can identify patterns and anomalies that suggest potential equipment failures before they occur. This allows for timely maintenance, reducing unplanned downtime and extending the lifespan of machinery. For example, Siemens uses AI to predict equipment failures before they occur, based on sensor data, which reduces downtime and maintenance costs.

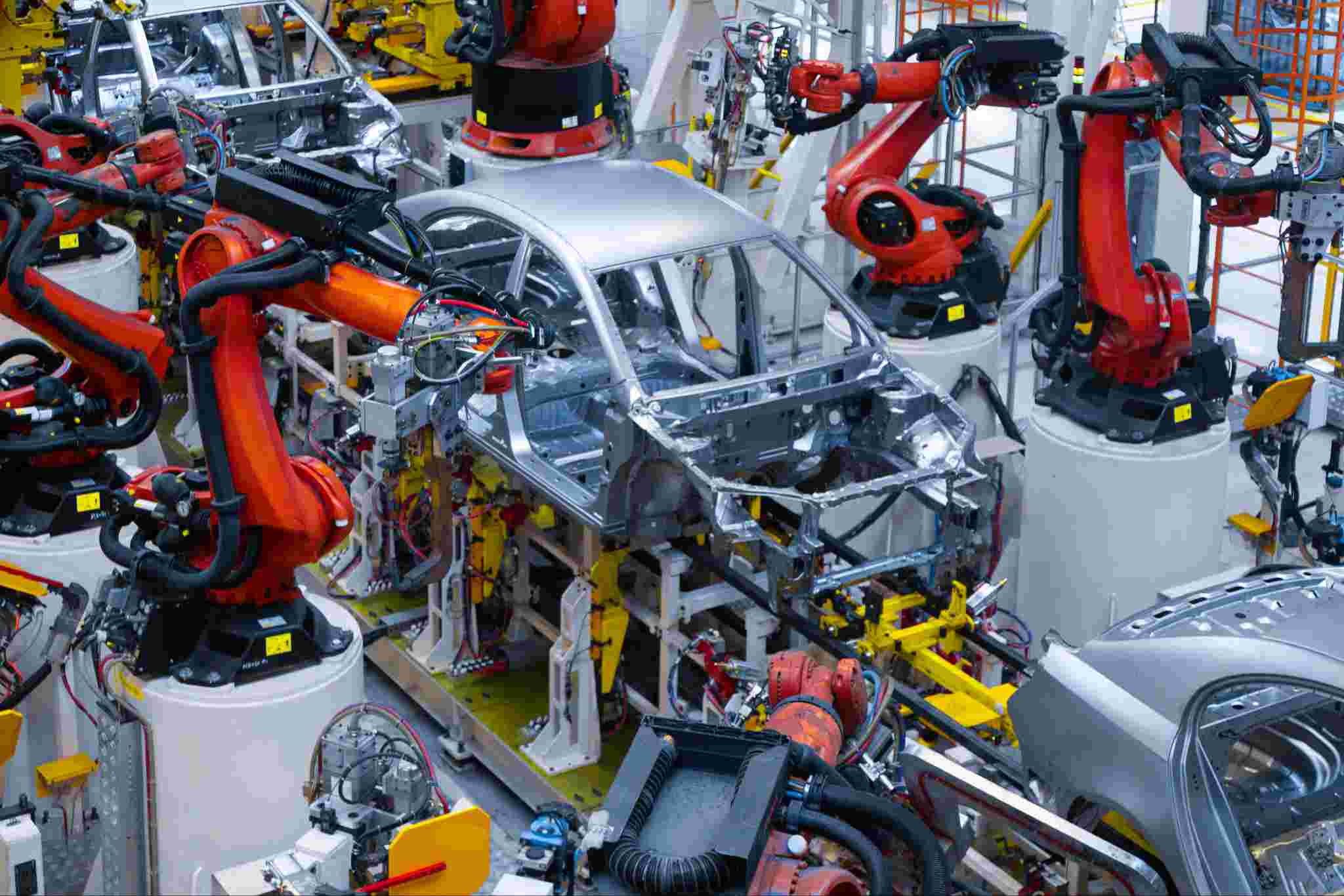

- Process Optimization AI in Action:

AI algorithms can dynamically adjust production processes in real-time, ensuring optimal performance. They can analyze current production data against historical trends to suggest adjustments to machine settings, workflows, and resource allocation. A renowned electronics company leveraged AI to optimize their SMT (Surface Mount Technology) lines, enhancing throughput and reducing waste. BMW employs AI-powered visual inspection systems to detect defects and ensure high-quality production.

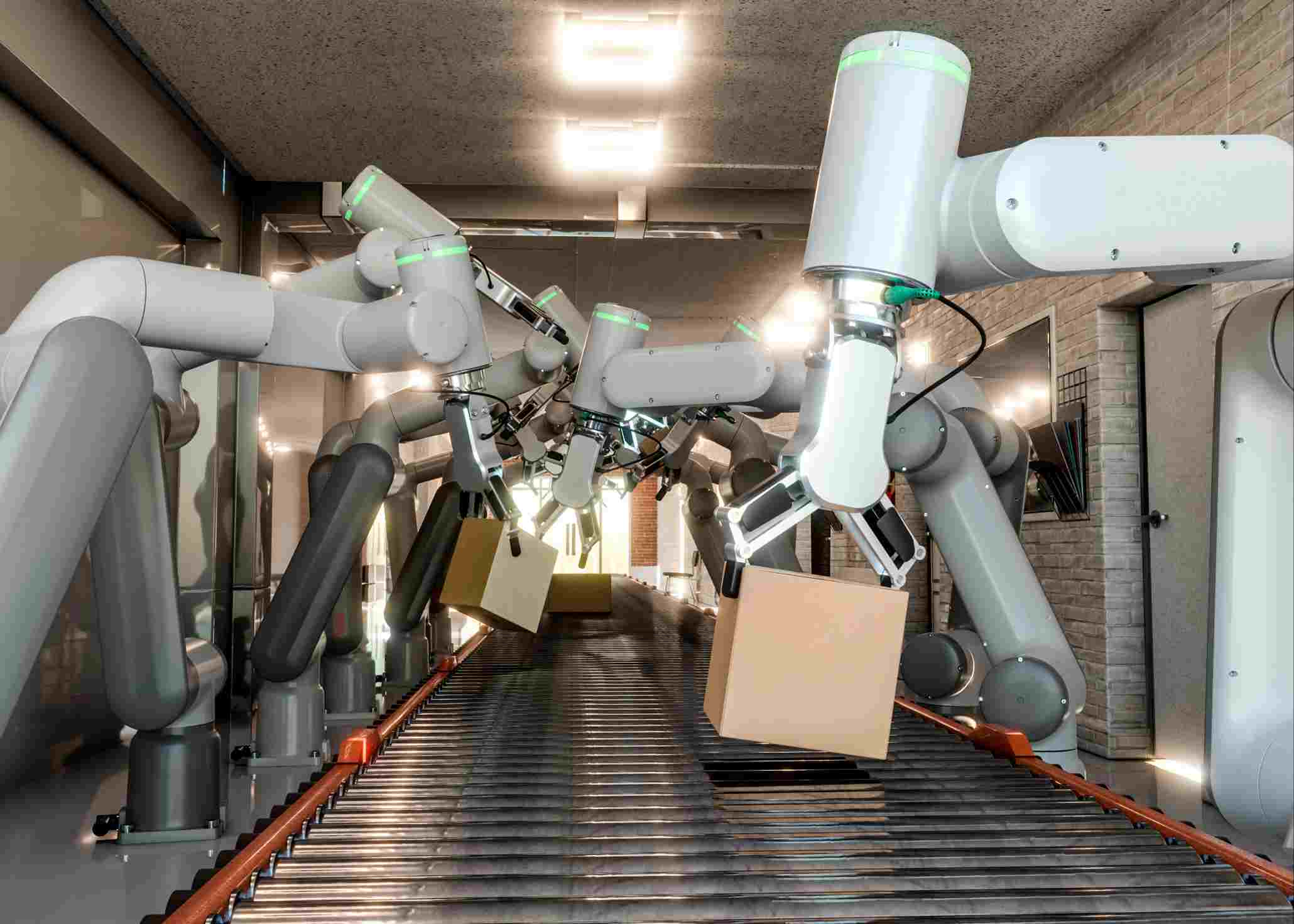

- AI Manufacturing Robots:

These robots are designed to work alongside human workers, taking on repetitive and hazardous tasks to improve safety and efficiency. They can adapt to new tasks through machine learning, becoming more efficient over time. An AI robotics firm has successfully deployed such robots across various sectors, demonstrating a 40% improvement in task efficiency. Fanuc’s industrial robots use AI to learn and improve tasks over time, enhancing automation efficiency.

- AI Production Systems for Quality Control:

AI-driven visual inspection systems can process and analyze images of products at high speed, identifying defects with greater accuracy than the human eye. This not only improves product quality but also speeds up the inspection process. A consumer goods giant has adopted AI visual inspection, leading to a 50% faster quality assurance process. Canon is utilizing AI for product quality to analyze images of inspected parts and automatically identify defects.

- Customization at Scale with AI:

AI enables manufacturers to offer personalized products without compromising on production efficiency. By using AI to analyze customer data and preferences, manufacturers can produce customized items on a large scale. A sports equipment brand has utilized AI to offer personalized gear, achieving a customer satisfaction rate of over 90%.Adidas uses AI to offer customized shoe designs manufactured on-demand using 3D printing technology.

- Supply Chain Optimization with AI:

AI can forecast supply chain disruptions and optimize inventory levels by analyzing diverse data sources, including market trends, weather forecasts, and supplier performance. A global tech company uses AI to manage its supply chain, which has improved inventory accuracy by 35% and reduced logistics costs by 15%. Intel uses AI to anticipate supply chain disruptions and adjust production plans accordingly.

- AI in Manufacturing Companies for Energy Savings:

AI systems can predict peak energy usage times and adjust machinery operation schedules accordingly, leading to significant energy savings. A steel manufacturer implemented AI-based energy management, resulting in a 10% reduction in energy consumption and a 5% decrease in carbon emissions.General Electric utilizes AI to monitor and optimize energy consumption across its manufacturing operations.

- Enhancing Human-Machine Interaction:

AI interfaces can translate complex machine data into actionable insights for operators, making it easier to manage and optimize production. An industrial equipment manufacturer introduced an AI-powered control system that improved user experience and operational efficiency by 20%. Nokia is using machine learning technology to monitor the assembly line process in its factories in Finland.

- AI for Sustainable Manufacturing

By optimizing resource use and reducing waste, AI contributes to more sustainable manufacturing practices. A textile company applied AI to its production process, cutting down on fabric waste and reducing water usage by 30%, demonstrating AI’s potential in promoting environmental sustainability. Ford employs AI-powered wearables to monitor the posture of assembly line workers, preventing injuries.

- AI-Driven R&D for Innovation

AI accelerates the R&D process by analyzing vast datasets to identify patterns and insights that can lead to new product developments. A pharmaceutical company used AI to sift through clinical trial data, reducing the drug development timeline by 25% and enhancing the success rate of new medications.Airbus leverages AI to simulate and test aircraft designs, streamlining the design process.

These examples showcase how is AI used in manufacturing industry, enhancing efficiency. It’s also evident that AI manufacturing, predictive maintenance, and process optimization AI are not just enhancing existing operations but are also paving the way for new levels of innovation and sustainability. As AI manufacturing companies continue to invest in AI production systems and AI manufacturing robots, the industry is set to witness a huge transformation in the coming years.

AI Manufacturing Companies: 5 Leaders of Innovation

The revolution of AI in manufacturing is being spearheaded by innovative companies dedicated to developing cutting-edge AI technologies. By offering advanced AI production systems and AI technologies, they answer the pivotal question: “How can AI help manufacturing?” There is anAI in manufacturing companies tailor AI solutions that enhance how manufacturing operates, from the deployment of AI manufacturing robots to the integration of complex AI algorithms.

1. DataToBiz:

This AI/ML product development company offers a range of services tailored to manufacturing enterprises. They specialize in creating custom AI models that can be deployed and integrated into existing systems. Their solutions aim to improve operational efficiency, provide deep insights through data analytics, and enhance decision-making processes. DataToBiz’s expertise in predictive analytics also helps manufacturers anticipate maintenance needs and optimize production schedules.

2. SoluLab:

With a strong focus on digital transformation, SoluLab provides AI solutions that streamline manufacturing operations. Their services include developing AI-driven systems that can manage and analyze large volumes of data from the manufacturing floor, leading to improved process optimization. SoluLab’s AI tools help manufacturers reduce waste, increase production speed, and maintain high-quality standards.

3. ASUS AICS:

ASUS AICS is pushing the boundaries of AI in manufacturing with solutions that prioritize safety and efficiency. Their deep learning models are designed to monitor manufacturing environments and identify potential safety hazards, helping to prevent accidents before they happen. Additionally, ASUS AICS’s AI technology assists in optimizing production lines and improving overall factory performance.

4. Invisible AI:

As a startup, Invisible AI offers an end-to-end hardware and software solution to track manual assembly processes. Their proprietary algorithms automate assembly line monitoring using cameras and a no-code platform. The AI platform keeps an eye on assembly operations and delivers actionable insights to factory managers, engineers, operators, and executives. Invisible AI generates a high return-on-investment (ROI) by improving quality, performance, and operational efficiency.

5. IBM:

IBM’s suite of AI solutions, including Watson, provides predictive intelligence and automation features that enable manufacturers to gain valuable insights and optimize their production lines. IBM’s AI tools are designed to track business trends, anticipate potential risks, and determine the best ways to incorporate automation technology.

As we witness the transformative impact of AI on the manufacturing sector, it’s clear that the companies developing these technologies are the true catalysts for change. They are redefining the essence of AI manufacturing, enabling predictive insights, and driving process optimization AI to new heights. With each advancement, these pioneers are not just reshaping an industry; they are reimagining the very fabric of production and innovation.

Conclusion: How Can AI Help Manufacturing Evolve

As we reflect on the transformative journey of AI in manufacturing, it’s evident that the convergence of AI manufacturing robots, predictive maintenance, and process optimization AI has set the stage for a new industrial paradigm. This evolution is not just about the adoption of AI production systems; it’s about reimagining how AI can help manufacturing sectors become more resilient, efficient, and innovative. The collaboration between AI in manufacturing companies and the users is crafting a future where AI in the manufacturing industry is synonymous with progress and competitive advantage.

The role of AI in the evolution of manufacturing is undeniable. The synergy between AI manufacturing, predictive maintenance, and process optimization AI has proven to be a catalyst for growth and innovation. As AI manufacturing companies continue to integrate these technologies, they pave the way for a smarter, more sustainable industry. The question is no longer if AI will transform manufacturing, but how we will harness its full potential to revolutionize the way we create, maintain, and innovate for the world of tomorrow.

Offices

India

86P, 4th Floor, Sector 44, Gurugram, Haryana 122003Singapore

#21-02, Tower 2A, The Bayshore condo, Singapore 469974Canada

8 Hillcrest Avenue Toronto ON M2N 6Y6, CanadaUS

31 River CT, Jersey City, New JerseySubscribe to our newsletter

Our Services

Top Reads

India

86P, 4th Floor, Sector 44, Gurugram, Haryana 122003

Singapore

#21-02, Tower 2A, The Bayshore condo, Singapore 469974

Canada

8 Hillcrest Avenue Toronto ON M2N 6Y6, Canada

US

31 River CT, Jersey City, New Jersey

Contact us

info@primathon.in

+91-9205966678

Reviews